A Guide to Metal Options

As an artist blacksmith who works in many different materials I have been asked for a lot of particular metal options. As a result I’ve looked into and experimented with a lot of different kinds of metals.

Since I frequently discuss different metal options with my clients, I have decided to put all the information in one accessible post.. As a blacksmith, I have added some particular information about forging.

You can use this as a guide when weighing different metal options.

Black Metals - Iron and Steel

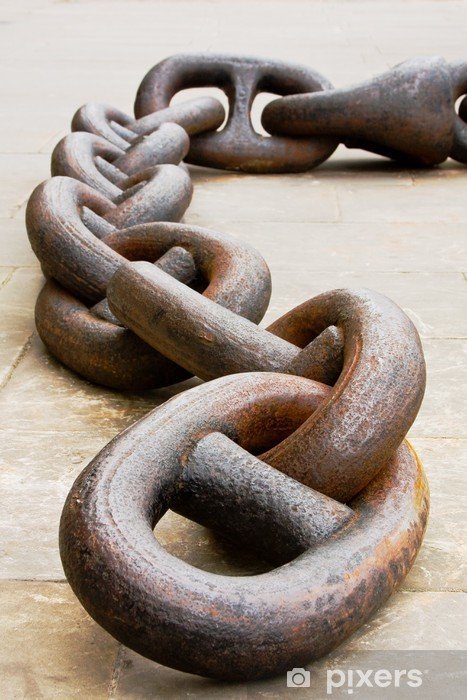

(From L to R) Cast Iron Panel, Wrought Iron Chain, Forged Steel Leaves

STEEL What we call steel can be many different things, but most commonly ornamental ironwork is made from steel that has about .2% carbon. Carbon is a tiny but very important part of iron and steel. Steel is the most common metal used in welding fabrication. It can also be forged into beautiful shapes by a blacksmith and often welded and sanded.

CAST IRON is iron that is melted and poured. It contains 1-2% carbon. It can contain almost 10x more carbon than mild steel. Cast iron can look beautiful, but often it has a sandy texture from the mold and visible seams. It is very brittle compared to steel and is likely to break rather then bend if hit by a force.

WROUGHT IRON was made by using a process that is no longer in practice today. Wrought iron has impurities such as silica and phosphorus. When wrought iron wears down you will often see a grainy wood like texture. It was widely used in making gates, railings, wagon wheels and bridges. The Eiffel Tower is made from wrought iron. I believed wrought iron was so named because it was often forged or wrought into shape. Forged iron is still sometimes referred to as wrought iron. Blacksmiths often seek it out because we find the texture and consistency compliments our work.

Copper Alloys: Copper, Brasses and Bronzes

(From L to R) Copper Watering Vines, Architectural Bronze Cap Rail, Naval Bronze Foot Rail, Aluminum Bronze Seahorse, Silicon Bronze Towel Ring, (All created by Celeste Flores of Clay and Steel), White Bronze Casting Ingnots.

COPPER - I do not personally use copper much for building as it is a very soft material and not appropriate for all applications. It patinas easily, which is sometimes desirable. It is often used on rooftops, where they frequently turn green. The Statue of Liberty is probably the most iconic example of a copper patina. The de Young Museum in Golden Gate Park has a copper sheath which has remained brown for over a decade. If you are not in a salty environment you can expect your copper to turn brown with maybe some varied colors developing over tim

BRASS AND BRONZE - What is the difference between brass and bronze? They are both copper alloys. A common definition is that brass is copper is alloyed with zinc and bronze is copper alloyed with tin. As far as I know the use of the term bronze is not regulated and so bronze can be many various kinds of alloys. I have laid out some common options below

ARCHITECTURAL BRONZE- Is a type of brass with about 60% copper and 40% zinc. It is often alloyed with 2-3% lead. It is very yellow in color but can be patinaed various colors. It can look just like bronze when patinaed. It is not a forgable alloy and is very brittle to work with. It pairs well with cartridge brass and other brass alloys. In my experience, I think it is probably the alloy most commonly marketed as bronze for decorative architectural purposes.

NAVAL BRONZE Naval brass is a historic alloy used for maritime applications. Originally it was categorized as bronze it is often still referred to as a bronze. It is about 60% copper, 39% zinc and 1% lead. It is similar in color to architectural. It is very soft and easily forgeable. It can take on many patinas including bronze colored patinas that will usually last outdoors for many decades.

ALUMINUM BRONZE - I really like aluminum bronze because it has a gorgeous light gold color. It is 84% copper, 11% aluminum, 4% iron and has some nickel as well. Indoors it maintains a golden patina. Outdoors it may start to brown and I have even heard of instances of rust because of the iron in the metal. That said, I know it can also last decades outdoors maintaining beautiful brown/bronze color. It patinas easily.

SILICON BRONZE- This is a bronze that metal artists ooooh and ahhh over. It’s expensive, costing twice as much as all other copper alloys. Bronze sculptures are often cast in silicon bronze. Newly polished forged bronze tends to have a beautiful rose gold hue but will turn a classic bronze color after a few weeks. It is beautiful with or without a patina. It never turns yellow. It can take a wide variety of patinas.

Silicon bronze, Naval bronze with antique patina, aluminum bronze

WHITE BRONZE- The composition of this alloy varies. It is used in casting and not forging, so I do not usually work with it. From looking at the white bronzes sold for casting from Bellmont Metals I know that it frequently contains 55-65% copper, with varying amounts of zinc and tin. It may also contain large quantities of manganese and 1-2% lead. Like architectural bronze or naval bronze it’s debatable as to whether this should be categorized as bronze. Many alloys of white bronze turn a dull gray overtime. This makes sense to me, as both zinc and tin both oxidize to gray. I imagine it can be polished to bring back the finish.

“Silver” Metals:

(From L to R) Stainless Steel Door Pull by Clay and Steel, Aluminum Handrail by Clay and Steel, Gate on the Guardian Building Detroit (artist unknown), Titanium Spork and Bowl by Ben Tendrick

STAINLESS STEEL is not stain free, it is only stain less. Any small amount of iron or oxidation contamination can make stainless steel rust. Large industrial manufactures have the means to chemically clean stainless steel to keep the surface pristine. Small or independent manufacturers may know how to work with this material to varying degrees. Many know how to fabricate stainless steel but not chemically treat it. As a blacksmith, I avoid using this material as the process to clean and treat it is laborious and expensive, involving immaculate mechanical cleaning followed by a chemical treatment.

ALUMINUM gets a bad reputation. When forging it is almost as soft as hammering oil based clay. It takes on texture easily. I think it can be a great option for a silver or white metal in architectural applications. However, when experimenting with small scale aluminum the weight and texture can feel insignificant to me. It can be great outdoors but needs to be anodized, powder coated or electropolished. Aluminum oxidizes quickly and will become chalky white and brittle if not treated correctly. Aluminum can be dyed to great effect. Remember early i-phones with their candy colors and the popular rose gold finish? Those were all anodized aluminum. It can also look very beautiful when machined or hand formed from sheet metal. Lots of parts on custom hot rods and motorcycles are made from hammered aluminum.

MONEL is my favorite “silver” metal in appearance and application. It is an alloy of nickel. I think it looks slightly warmer than stainless steel. It has corrosion resistance similar to bronze. As far as I can tell it will stay a beautiful warm silver for the life of the material. It is a hard material but still forgable. There are two downsides to this material. First, it costs a lot. It costs twice as much as silicon bronze. Second, a very large percentage of the population has a nickel allergy. Many common items are plated nickel and they do not bother people who have that allery. I would still recommend all monel be lacquered so that there is a coating between the metal and the user.

TITANIUM is not widely considered as a building material but can be used decoratively for small items, such as hardware. It has a bright and shiny appearance similar to chrome. It can be forged but is very hard. It is difficult to machine. Heat can be used to create a bright and colorful oxidation appearance. Because fabrication of titanium is difficult and the material is expensive it is certainly not practical for all applications. I haven’t experimented with it much but I wouldn’t rule it out for the right job.

This list isn’t comprehensive. And much of it is based on my own experience. I’m always happy to experiment with new materials and finishes. I am especially curious about silver plating brass for the right client. I will update this if I ever conduct those experiments. I am very open to thoughts and questions on this subject.